Page 24 of 28

Re: Copenhagen Fields & TFW’s workshop

Posted: Wed Jan 25, 2023 12:18 am

by Tim Watson

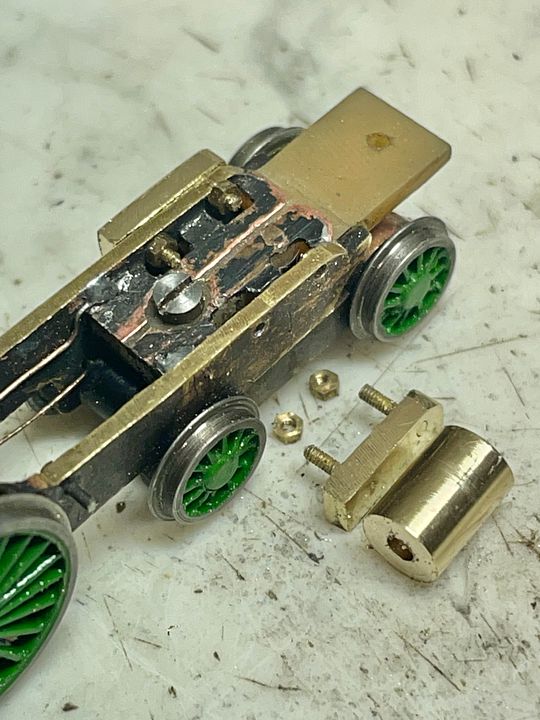

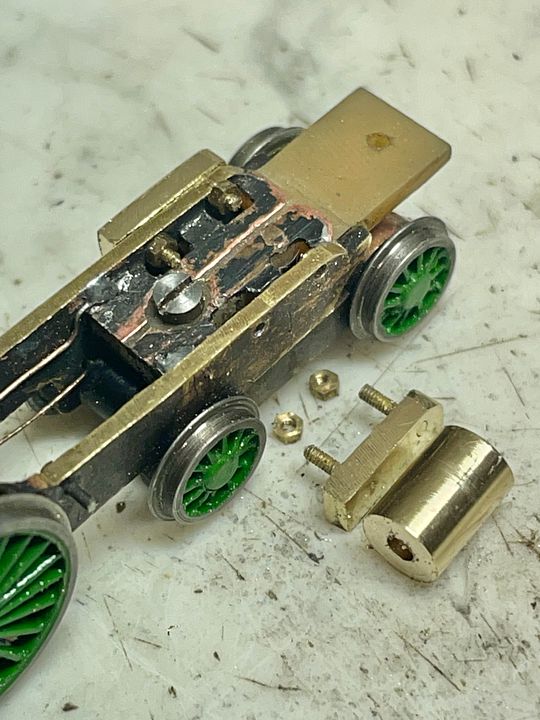

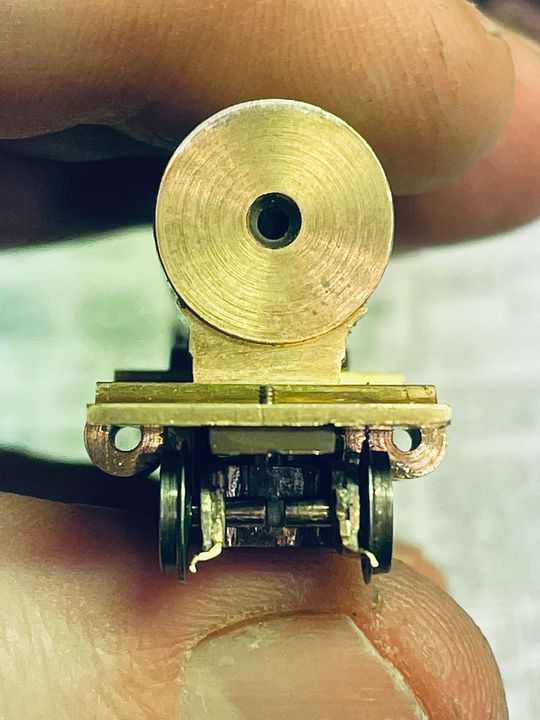

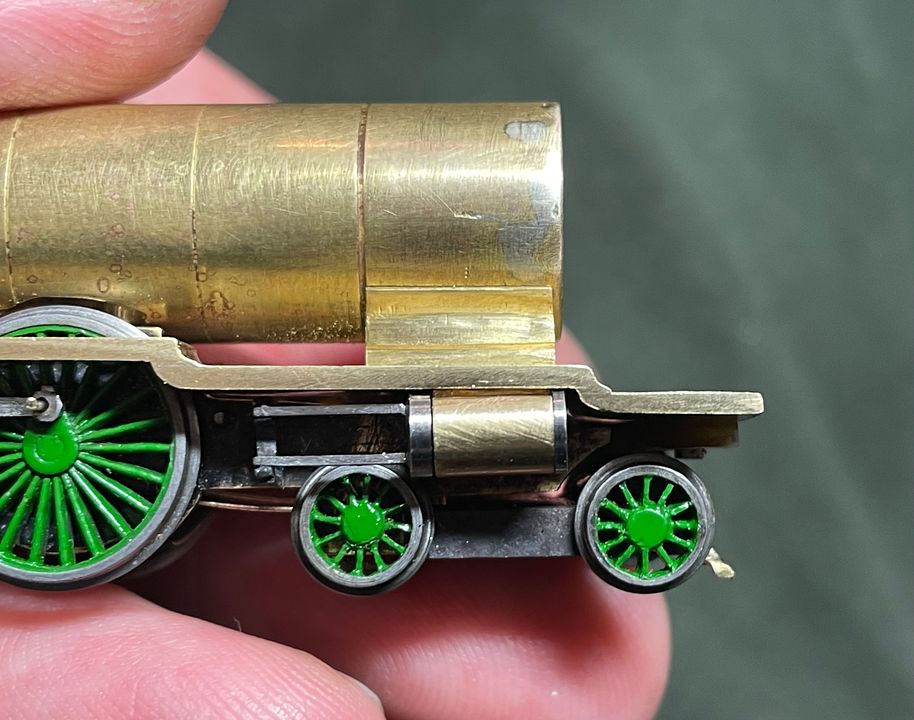

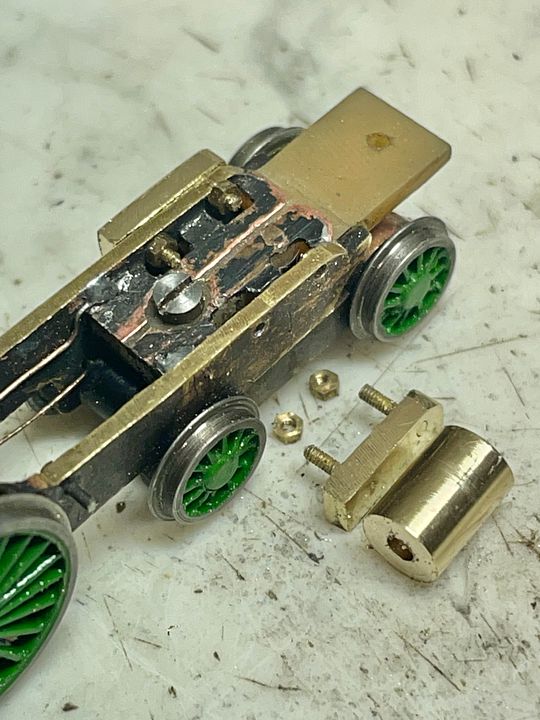

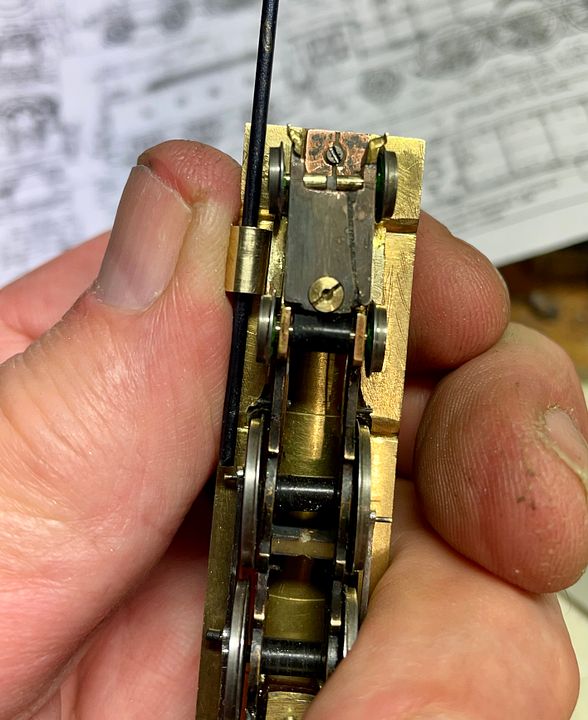

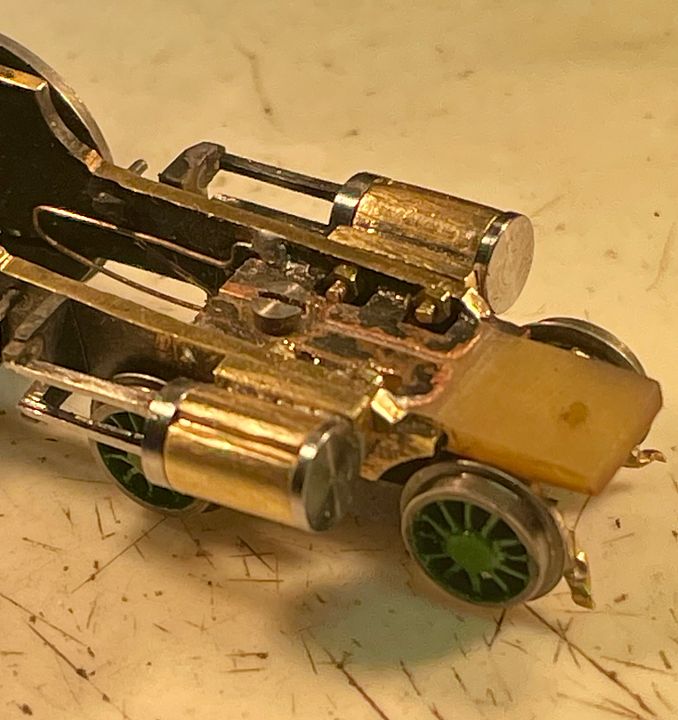

Attention has now turned to the cylinders. These will be soft soldered to two pads which are, in turn bolted through the frames. The fixing studs are 16BA silver soldered in the brass block. The reasons for the square cut outs in the PCB spacer are now apparent, as they give room for the nuts. The cylinders will have polished steel end caps, as per the prototype, and it’s fortunate that the rear one is very simple, which will make machining the slide bars rather easier.

The cylinders are bored 1.5mm to take the front and back fittings. It’s also useful for checking alignment using a sighting rod. The cylinders are currently 0.5mm too wide on each side, but there should be ample clearance to bring them in to scale width.

The next job will be to file off the top of the cylinders to allow for their inclination, then solder them on to the pads.

Tim

Re: Copenhagen Fields & TFW’s workshop

Posted: Thu Jan 26, 2023 2:05 pm

by Tim Watson

Slight change of tack, but Copenhagen Fields will feature in the next episode of ‘Hornby a Model World’ on the Yesterday Channel (Freeview 27) on Monday 30/1/23 at 2000.

You will find out how this happy little scene was made:

As well as our trip with CF to the 2mm Association Derby exhibition in June ‘22.

Tim

Re: Copenhagen Fields & TFW’s workshop

Posted: Fri Jan 27, 2023 10:40 am

by Atlantic 3279

Quite an undertaking (groan). I thought I'd spotted you in the taster at the end of Monday's broadcast...

Re: Copenhagen Fields & TFW’s workshop

Posted: Fri Jan 27, 2023 3:25 pm

by S.A.C. Martin

Cannot believe I missed this - the A2 is looking superb Tim. Saw this as you shared on Facebook, and only just realised it is on here. Doesn't look 2mm scale (!)

Re: Copenhagen Fields & TFW’s workshop

Posted: Sat Jan 28, 2023 1:01 am

by Tim Watson

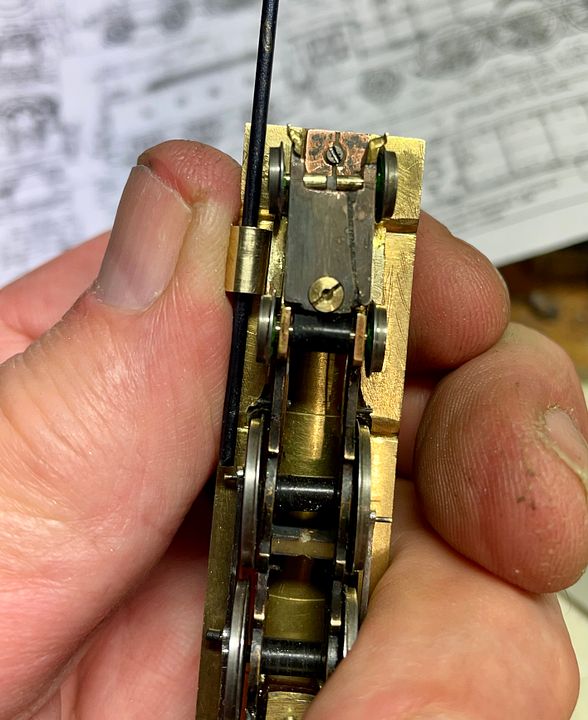

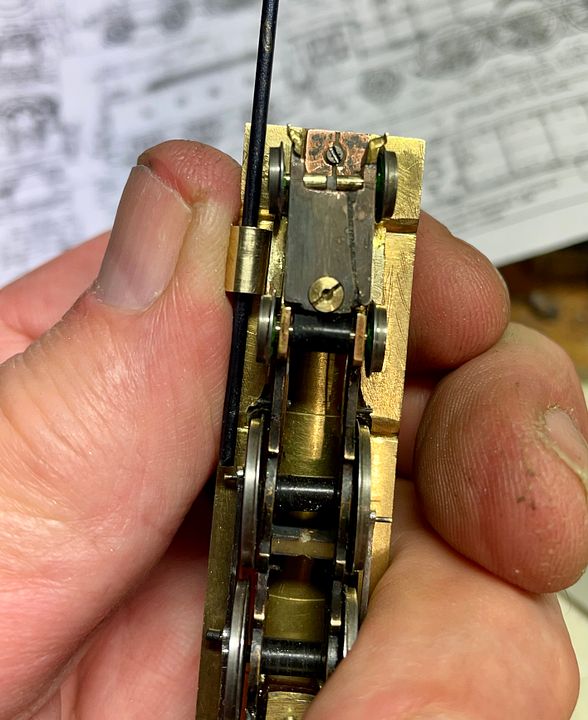

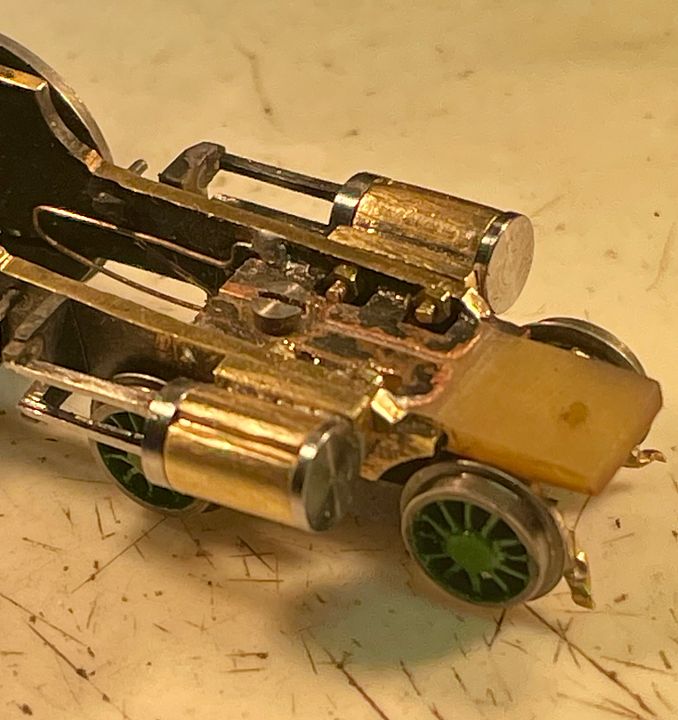

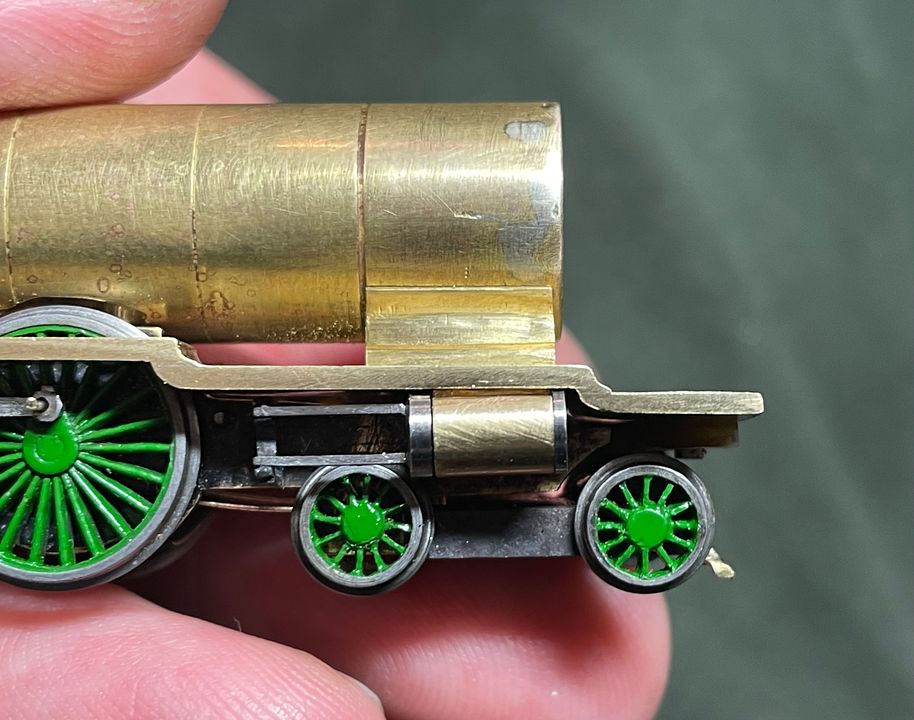

The cylinders have now been fixed to the frames on the NER 4-6-2 class. I decided against trimming the top of the cylinder but cut out the underside of the thick running plate instead. This gave a ‘cradle’ to support the cylinder whilst it was being soldered to the mounting pad.

The two components were held in place by hand against the frames, after tinning both pieces, but wearing two nitrile gloves. These don’t give that much heat insulation, but better than nothing. The alternative, which I tried on the second side was to use a piece of emery cloth to grip the cylinder and push it against the frames. The gloves worked better and the cylinder was just tacked into place with an exceedingly hot iron.

The assembly was then removed, clamped up with some locking tweezers and properly sweated together.

An air gap was cut around the cylinders using a fine bur and files to insulate from the bodywork (actually only needed on one side - the other is live). The cylinder had a small rebate cut into it so that it did not touch the valence: this may be coated in epoxy resin later on.

The positioning of the cylinders is very critical, the first one was OK, the second more tricky. From the front they look OK.

From the side the angulation is quiet subtle: the sighting rod helps to check it out.

Next bits to make will be the cylinder covers and slide bars. The rear cover is actually quite deep and incorporates the stuffing box, which will make constructing a bit easier.

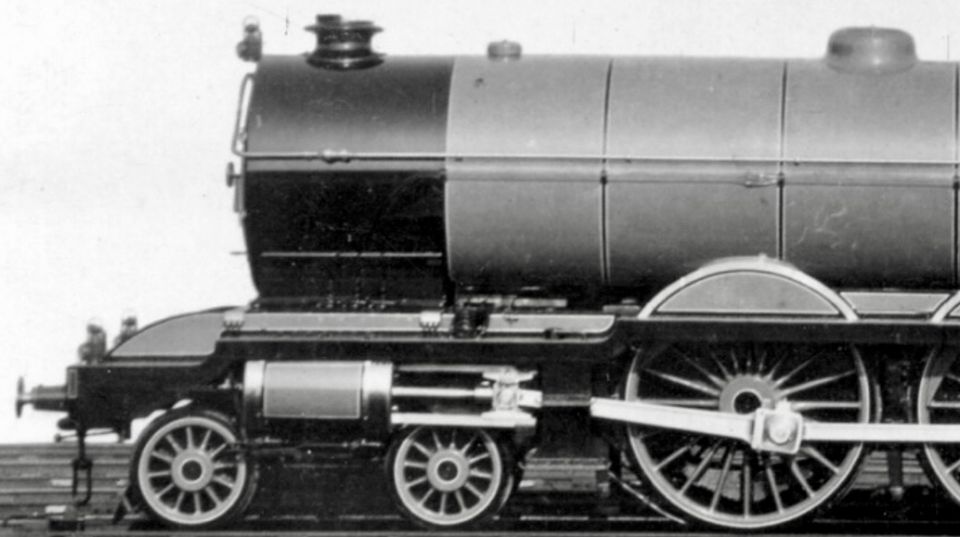

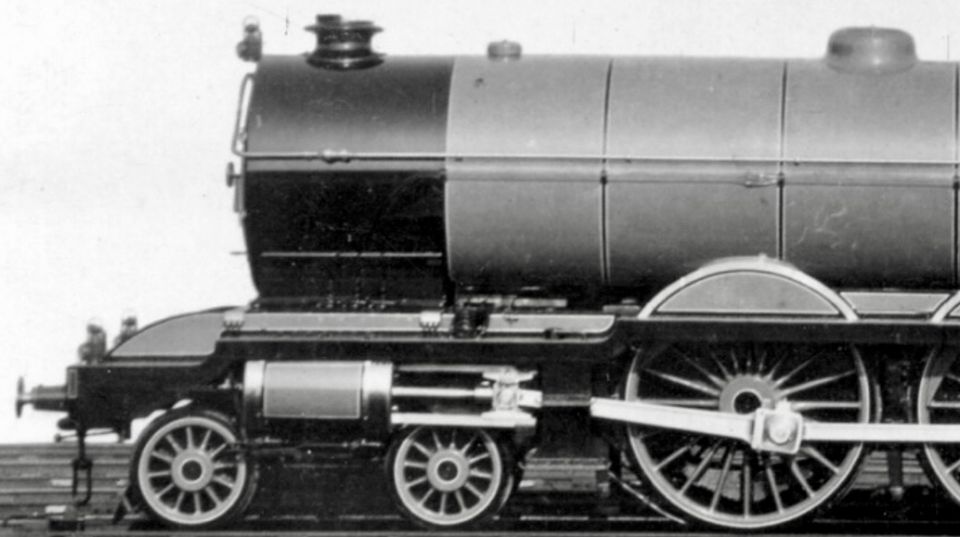

I really need to get a high resolution copy of the works photo of 2400; it has some good details in it.

Tim

Re: Copenhagen Fields & TFW’s workshop

Posted: Sun Jan 29, 2023 1:22 pm

by Tim Watson

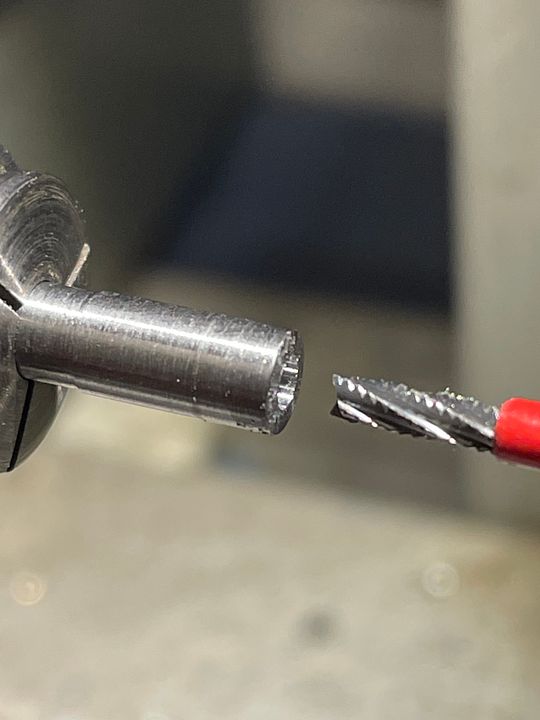

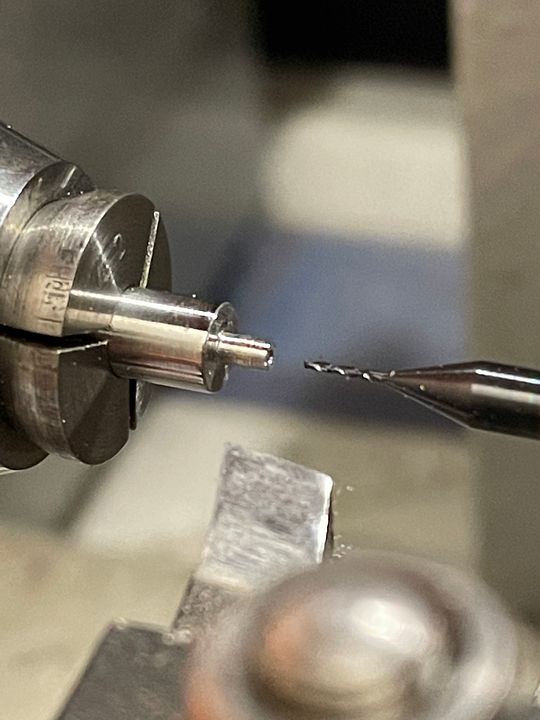

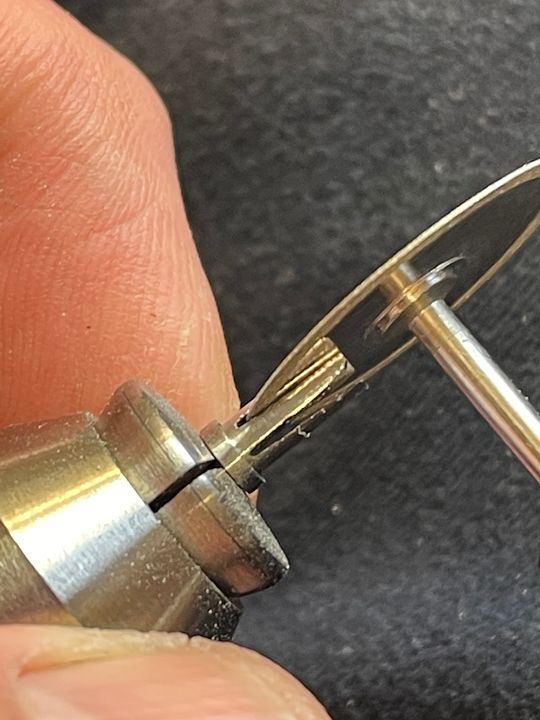

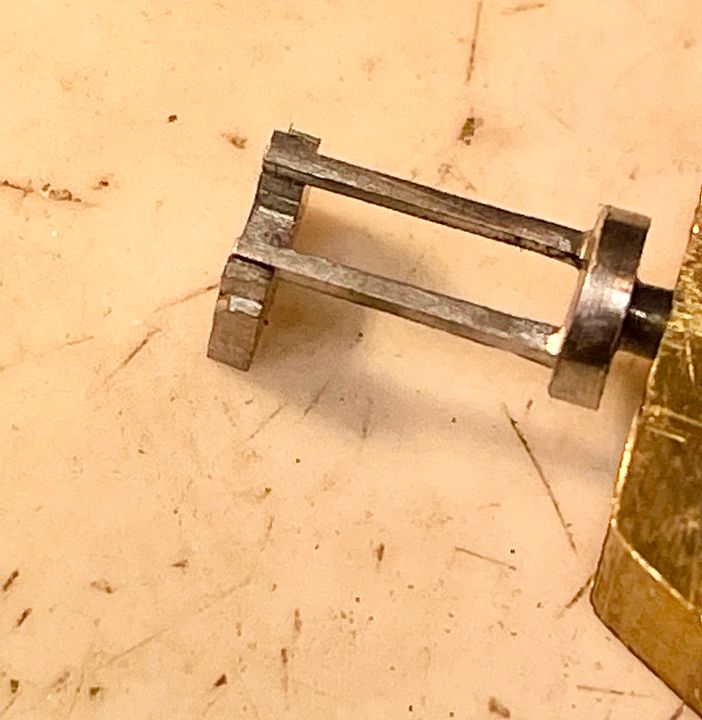

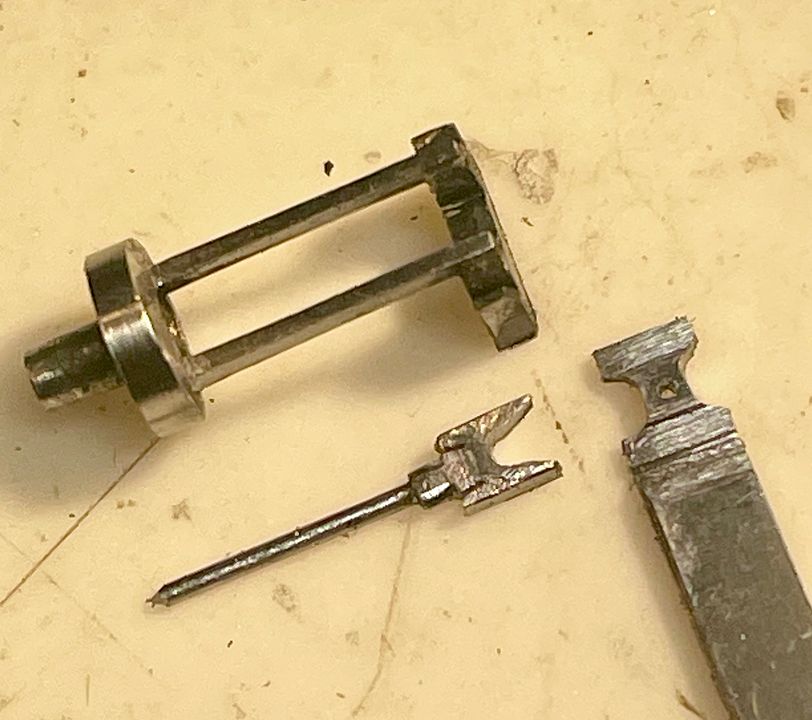

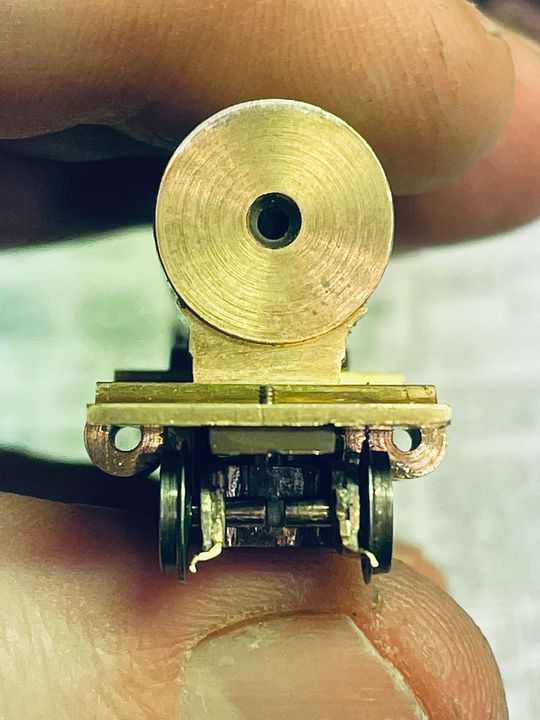

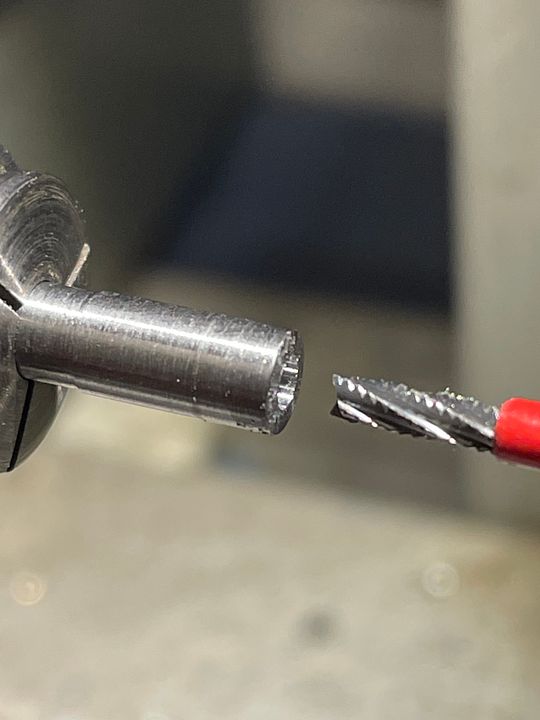

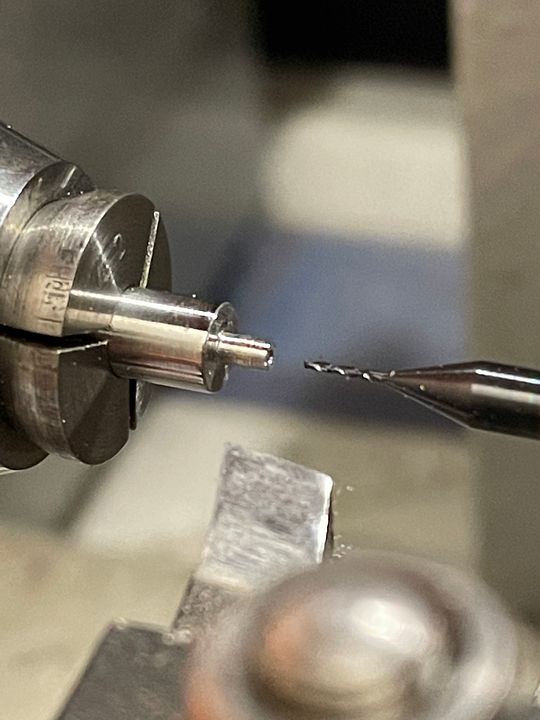

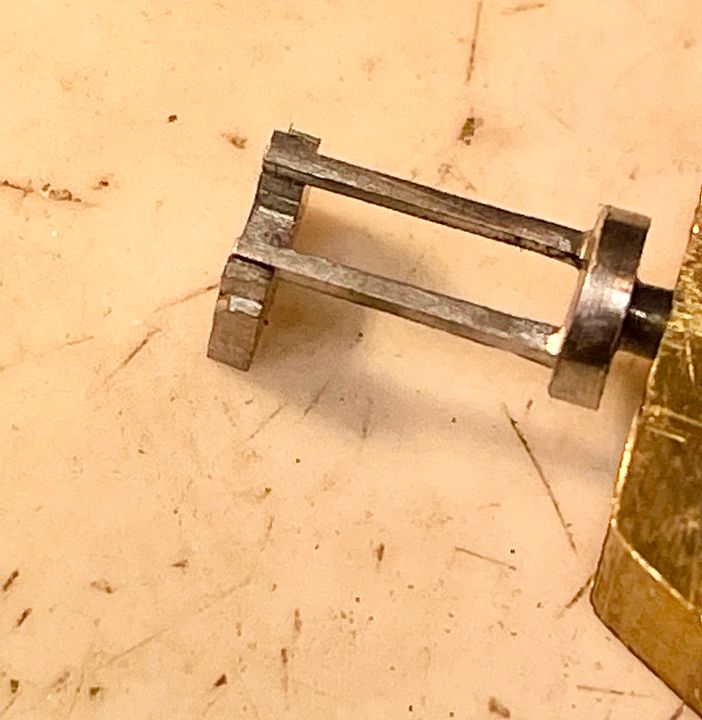

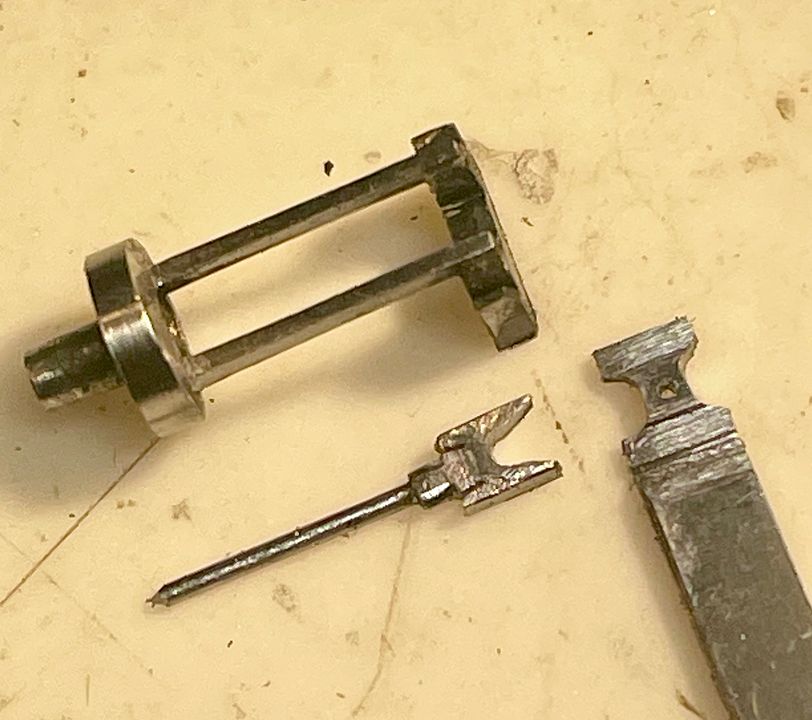

I do like making the ‘engine’ bits on steam locos. The slide bars are now 50% complete on the NER 4-6-2 class. I always make these types of slide bar as part of the cylinder back cover. The steel rod was drilled 1.9mm and then finished to 2mm diameter with a flat end mill. This gives the distance between the slide bars.

This was then turned down to 3mm diameter: the distance over the slide bars and then the actual cylinder diameter. This was reversed in the collet and turned down to 1.5mm - the bore of the cylinder. Finally, a 0.5mm hole was bored for the piston rod.

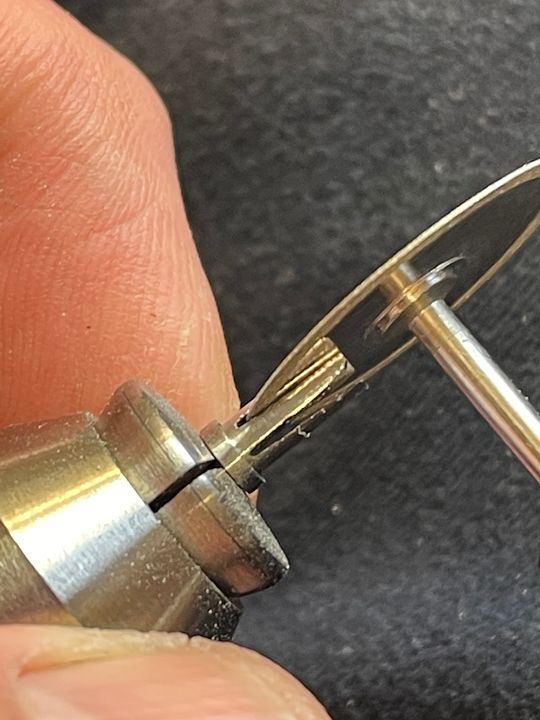

The next job was to cut down the sides of the ‘tube’ using a diamond disc to reveal two rather rough slide bars.

After some careful filing, using the piston rod to make sure everything is in-line and central, the slide bars are complete on one side - just got to do the other now.

The motion support bracket will help to protect the vulnerable ends.

Tim

Re: Copenhagen Fields & TFW’s workshop

Posted: Tue Jan 31, 2023 12:30 am

by Tim Watson

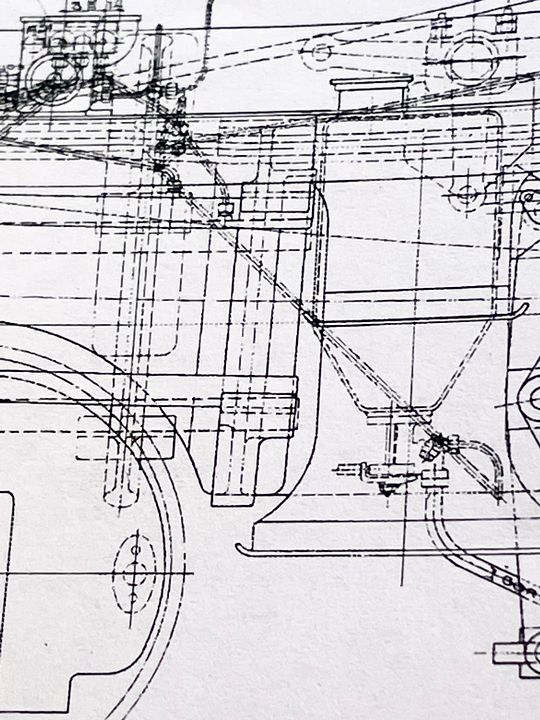

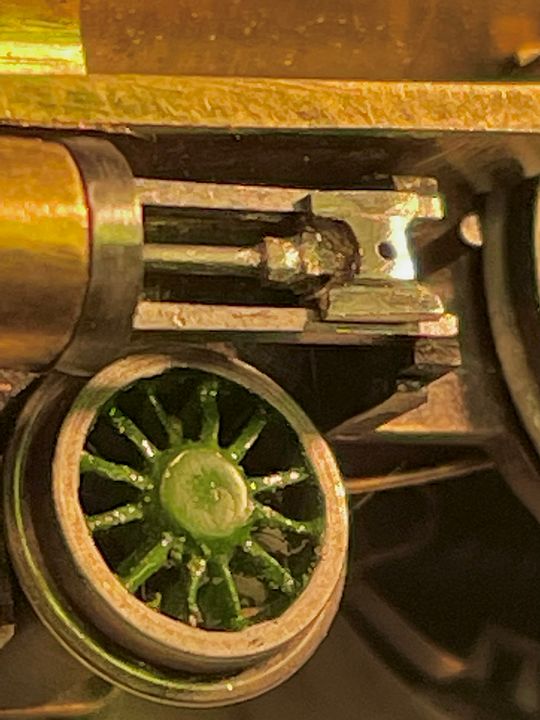

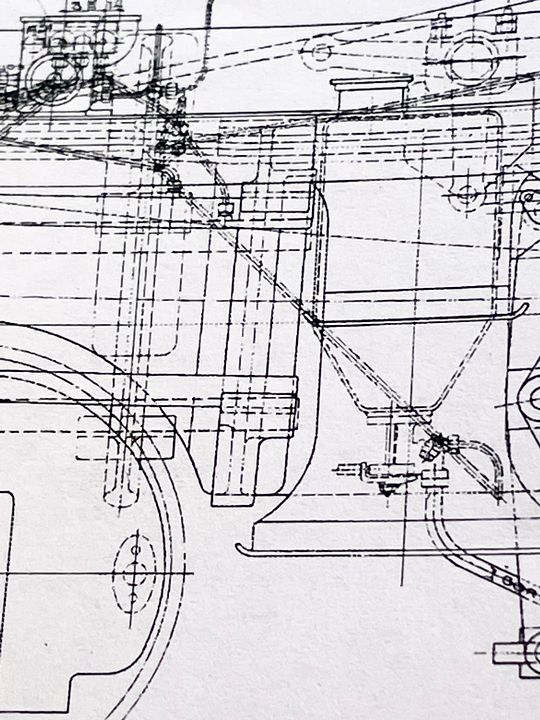

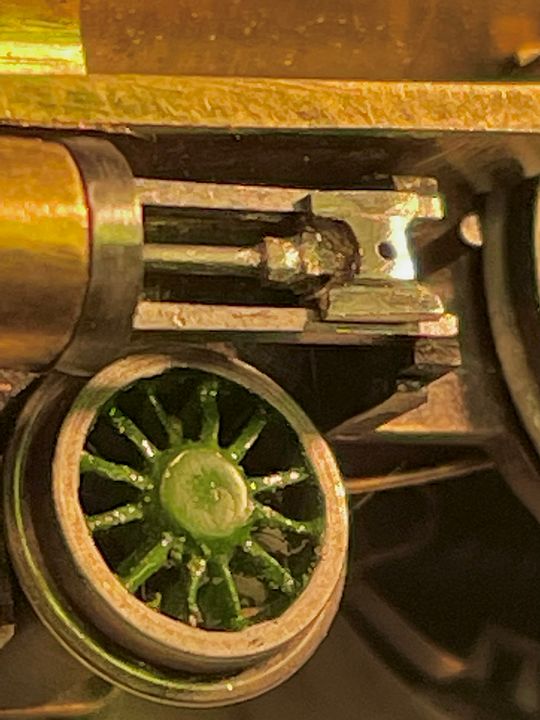

The motion support brackets for the Raven Pacifics was quite a chunky affair.

These were made from some 1mm thick steel - two pieces sweated together with soft solder. A number 6 cut Valorbe file with a safe edge was used to produce the rebates on the front edge of the bracket, which support the slide bar ends. Finger nails make good filing guides. All the soft solder must be removed before trying to silver solder.

A simple jig consisting of a hole in a lump of brass acted as an analogue for the cylinder, resting the slide bars on the bracket rebate.

This was then transferred to the charcoal block, a small amount of silver solder paste added and the joint heated with a fine flame.

The bits that might stay bright were cleaned up, but the rest of the bracket was left fire stained and black - saves painting.

The whole front end is beginning to get a bit more busy. I might thin the bars a little, when I have a fresh pair of eyes: taking photos is very useful for showing up dodgy bits.

After a bit of refining of the slide bars

Tim

Re: Copenhagen Fields & TFW’s workshop

Posted: Thu Feb 02, 2023 11:56 pm

by Tim Watson

It’s always a great feeling when a loco has a good first run on the MRC test tracks. The Skittle Alley easily started and ran with 18 on. She will probably take more but the loco and tender are minimally lubricated, so I didn’t want to push it.

https://youtu.be/jOJwYitotCQ

https://youtu.be/GSXv6ChzivE

Tim

Re: Copenhagen Fields & TFW’s workshop

Posted: Fri Feb 03, 2023 9:50 am

by mick b

Impressive!!

Re: Copenhagen Fields & TFW’s workshop

Posted: Fri Feb 03, 2023 11:10 am

by Atlantic 3279

I agree.

Re: Copenhagen Fields & TFW’s workshop

Posted: Fri Feb 03, 2023 1:08 pm

by drmditch

Likewise

Re: Copenhagen Fields & TFW’s workshop

Posted: Fri Feb 03, 2023 11:37 pm

by Tim Watson

Making things from scratch is sometimes more straightforward than using components from a kit, as you can design the bits to be held whilst working on them. This was especially true when making the first cross head for the NER 4-6-2 class. The inner crocodile was filed up from 1mm steel sheet, drilled in the end for the piston rod (0.5mm pivot steel) which was silver soldered in place. It was adjusted to be an easy sliding fit in the slide bars with the piston originally being very long to give something to get hold of. The outer pivot and slide bar slippers were made from 0.5mm steel sheet, centred on the 0.4mm diameter pivot hole for the little end, but again with a long handle still attached.

Having the handle to hold enabled easier filing of the appropriate rebates and surface details.

The two components were soft soldered together and, once the main filing was complete, cut off from the handle.

The connecting rod will have a 0.4mm diameter pin silver soldered to its end which will be the little end pivot. This will be retained by a small collar on the outside of the cross head, representing the prototype little end retainer.

I now need to finish off the second cross head and then the connecting rods. I much prefer steel for valve gear, it is stronger and, being harder, is more forgiving when filing up components - it takes a little longer so you have time to think before you make a mistake - if you understand my strange logic.

Incredible what iPhones can do isn’t it?

Tim

Re: Copenhagen Fields & TFW’s workshop

Posted: Sat Feb 04, 2023 9:51 am

by Jim de Griz

When I first started following this thread I seriously didn’t realise these are N Gauge models. The level of detail your adding….I’m astonished.

Jim de Griz

Re: Copenhagen Fields & TFW’s workshop

Posted: Sat Feb 04, 2023 11:46 am

by Atlantic 3279

I always became frustrated in the past when progress was slow. I still do in some cases, but I agree that slow progress can actually be an advantage, leaving plenty of opportunities to think several times about the way to tackle a job, leading to a greater likelihood of getting the right result from just one attempt.

Re: Copenhagen Fields & TFW’s workshop

Posted: Sat Feb 04, 2023 10:58 pm

by manna

G'Day Gents

I very much doubt that I could get that much detail on a 4mm model of an A2, we'll find out one day when I tackle one !

manna