Page 5 of 28

Re: Copenhagen Fields & TFW’s workshop

Posted: Sun Aug 18, 2019 1:31 am

by Tim Watson

Moving on to the engine bodywork, that clever Mr Easton uses a cradle to support the running plate. This makes it pretty simple to assemble. I did, however, use my own piece of larger 5thou NS sheet for the change in direction of the running plate behind the raised cylinder section - this will get trimmed to size later on. The supplied squiggly bit was just too small and fiddly.

Similarly, the front steps were made out of 5thou strip, being much easier to hold as well as being closer to scale thickness: they are quite large and thin on the real thing. The strip is held in place but notched where it needs to break before soldering into place.

The piano front between the frames was made from som 0.6mm thick NS filed to shape: it took quite a while to get it nice and snug.

Will soon separate the running plate from the jig and offer it up to the chassis. Kits certainly speed up construction.

Tim

Re: Copenhagen Fields & TFW’s workshop

Posted: Sun Aug 18, 2019 8:36 pm

by Tim Watson

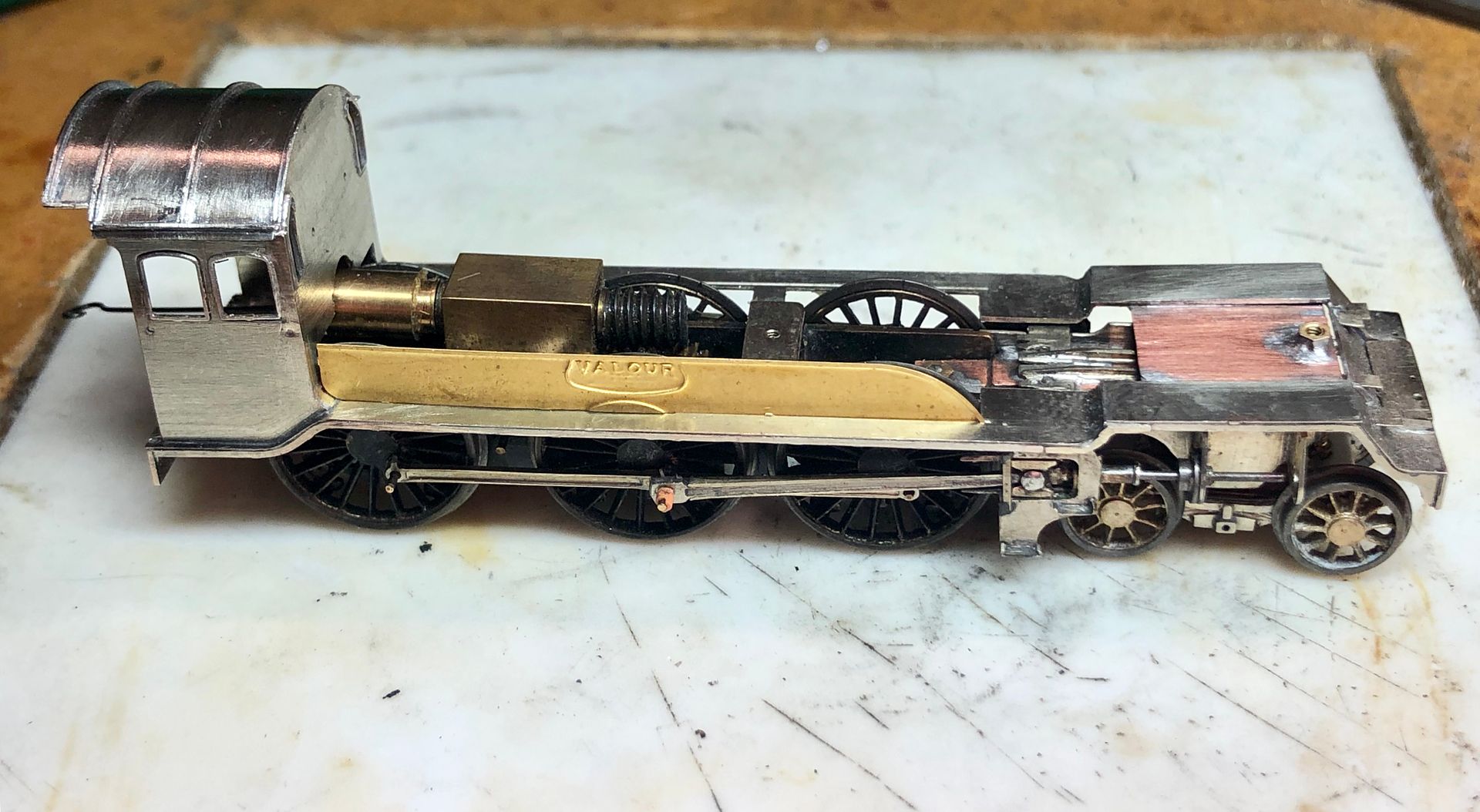

The running plate is now mounted on the chassis with three bolts to locate it. She now begins to look like an engine.

Thin double sided PCB, tucked up behind the valence, has been used to insulate the front running plate from the cylinder assembly. The smoke box will bolt through the PCB.

Tim

Re: Copenhagen Fields & TFW’s workshop

Posted: Mon Aug 19, 2019 9:08 am

by Atlantic 3279

Heartening progress.

Re: Copenhagen Fields & TFW’s workshop

Posted: Sat Aug 31, 2019 11:00 pm

by Tim Watson

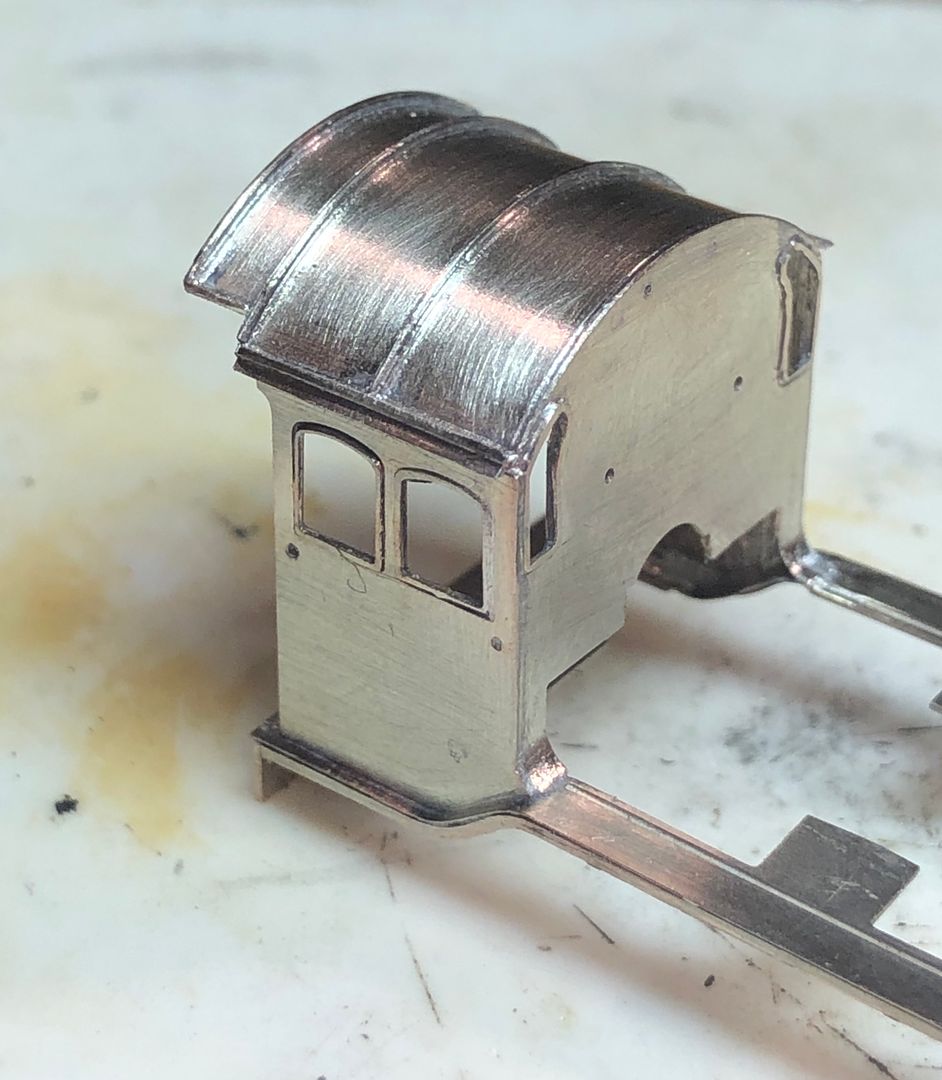

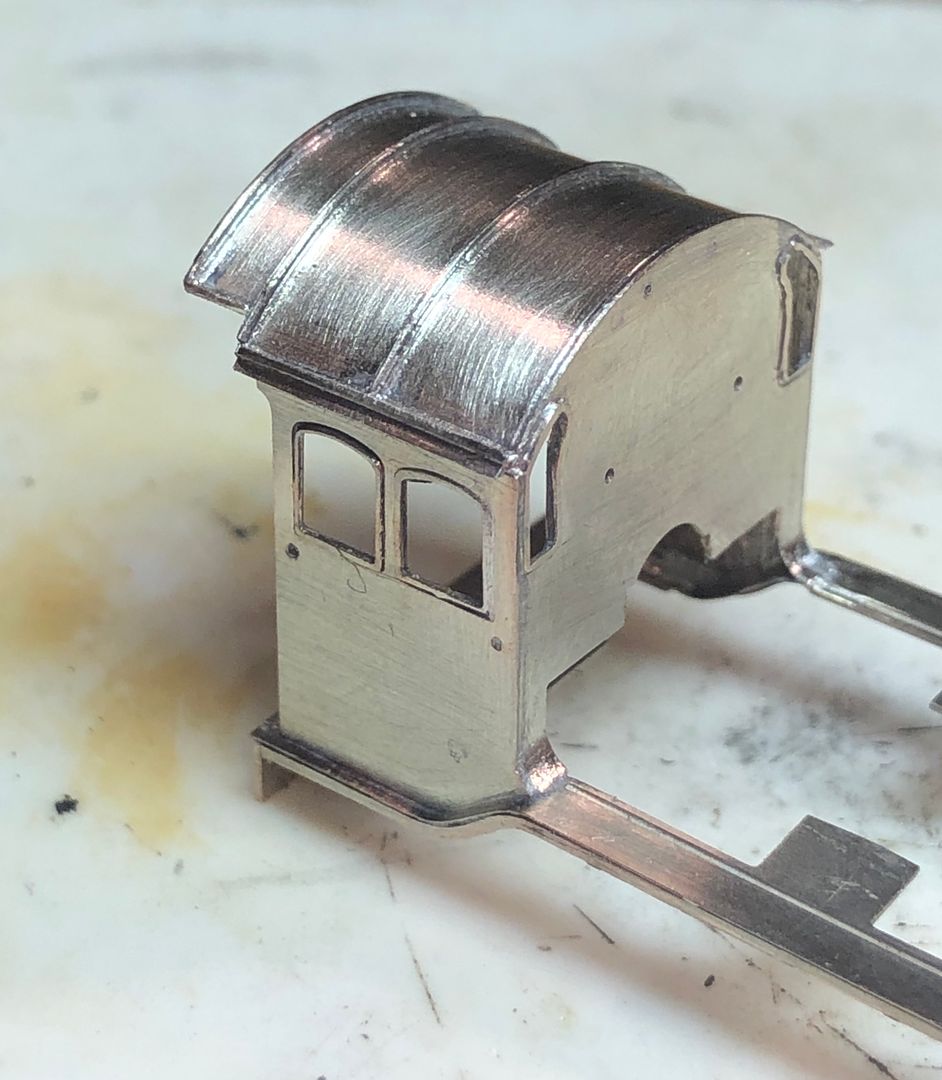

I’ve been working on Valour’s cab over the last couple of days. The windows have etched frames to be fitted - quite fiddly in fact. The front spectacle frames were too fine for use (over-etched for the thickness) and so some strip was bent up and soldered in place. The cab roof has some long slots left proud by half etching in order to accommodate the up right of the characteristic T section external roof ribs. These etched ribs were thinned down with a file to fit the slot and then soldered in place using my trusty surgical clips to hold them in place.

It was easier to solder the back rib in place with it still attached to the etch.

The roof is very rigid with the extra ribs.

I couldn’t resist putting the splasher with integral nameplate in place. It may, in fact, be the next job.

Tim

Re: Copenhagen Fields & TFW’s workshop

Posted: Sun Sep 01, 2019 11:41 pm

by Tim Watson

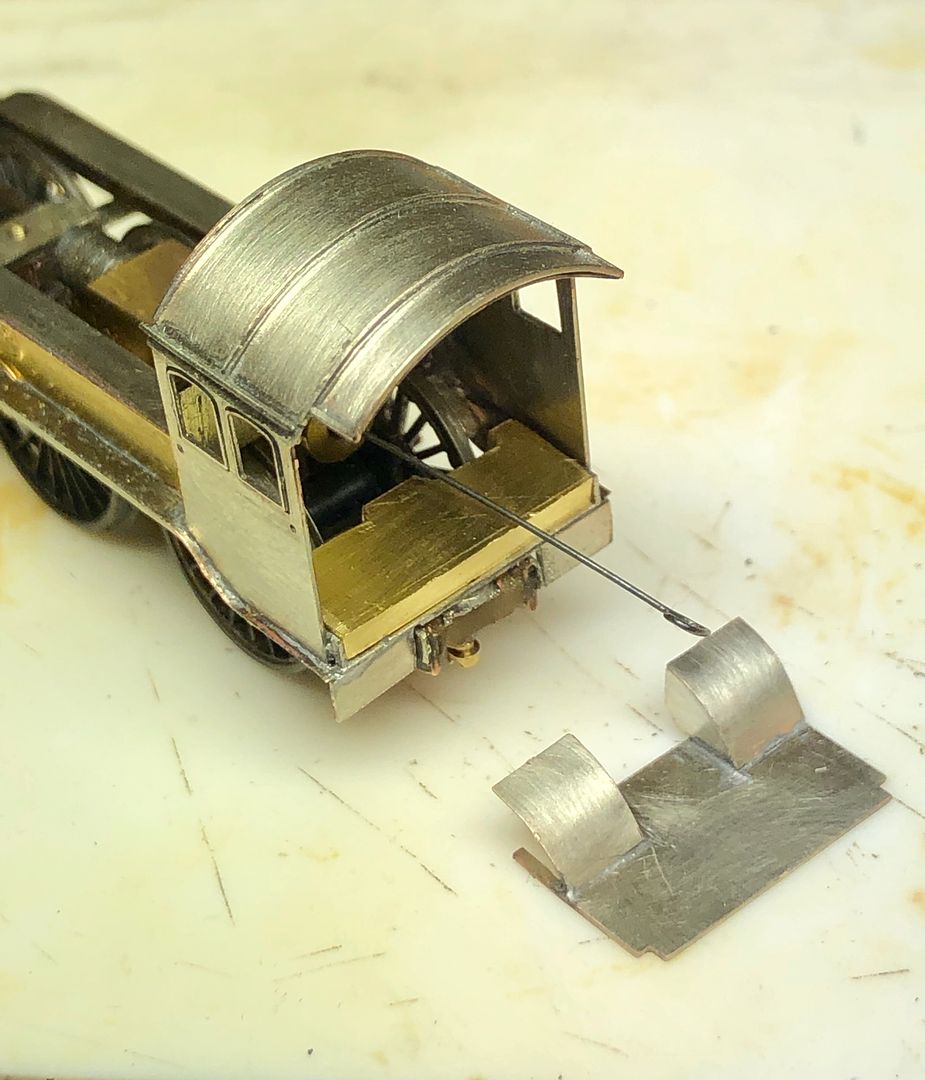

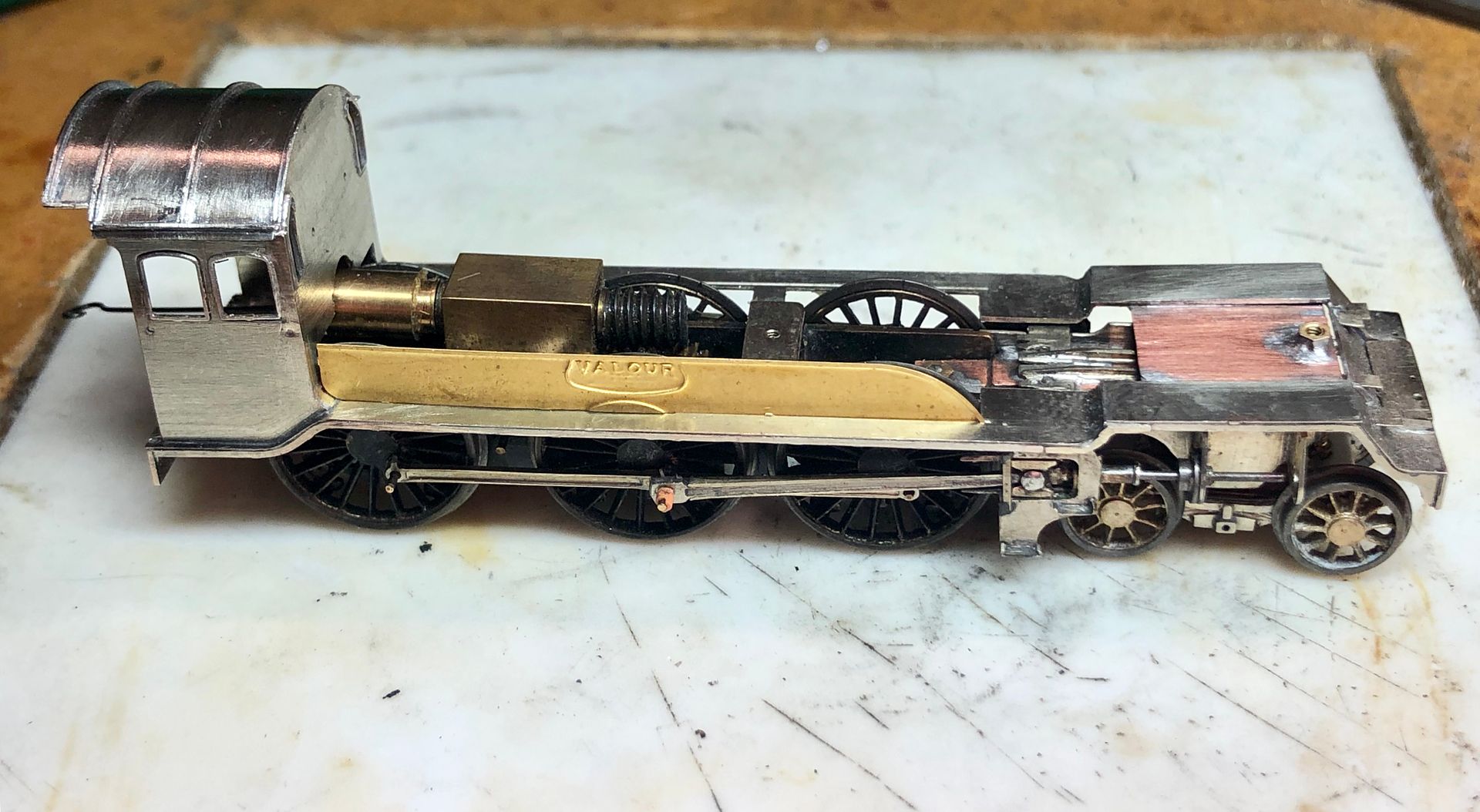

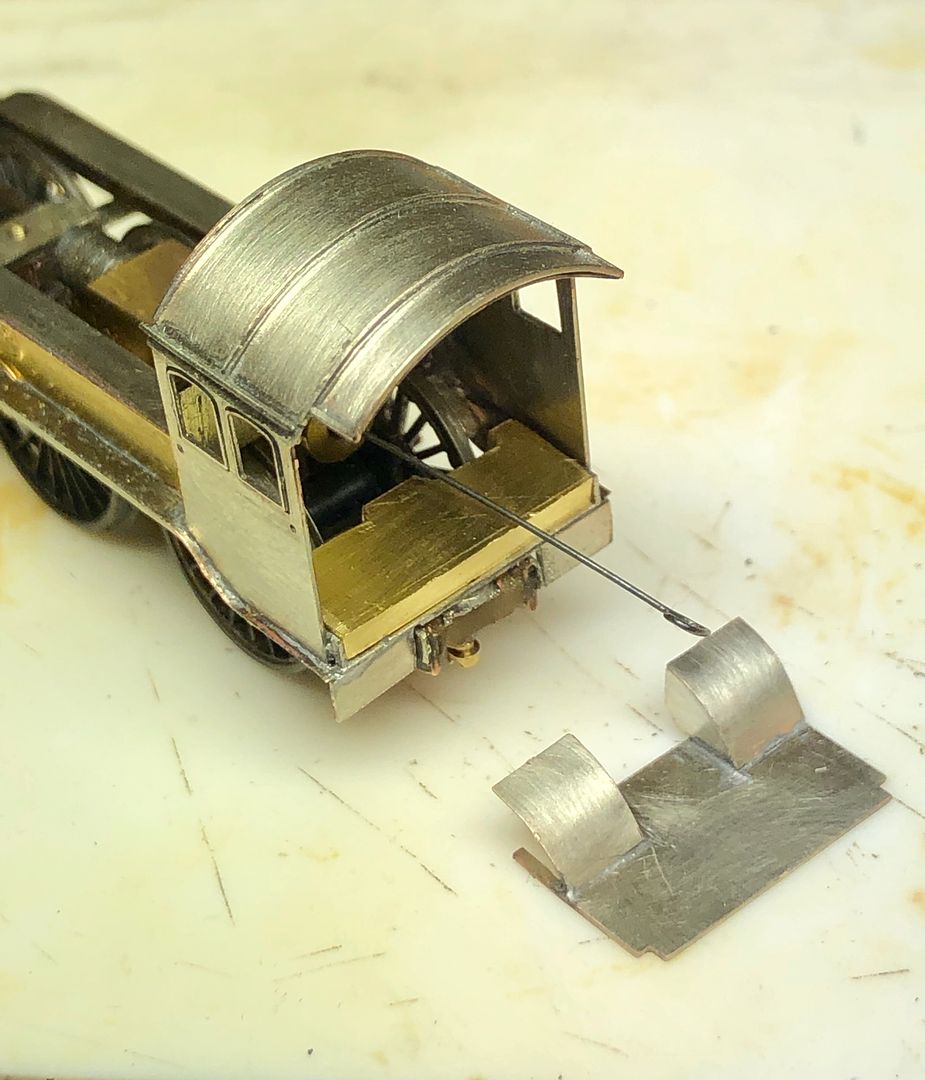

The splashers are now fitted and the cab footplate & inside splashers made. I have used a slab of brass to support the cab floor, putting weight where it’s needed. This will also be drilled and tapped to take a longer pivot screw for the tender.

The line drawn down the middle of the cab front corresponds with a line drawn down the underside of the cab roof, which helps to align the two (not my idea, but Graham Nicholas’ who wrote up the 4mm example instructions). The UJ cap will push forwards a little on final assembly and clear the back head which will be made as a brass lost-plastic casting and fixed to the removable footplate.

I’m not quite sure how to do the Belpaire firebox, as it is 45 years since I last made one. There are etchings included in the kit, which might wrap around a slightly reduced diameter boiler turning. There should be plenty of weight over the driving wheels, as the drive head sits nice and low between the splashers.

Tim

Re: Copenhagen Fields & TFW’s workshop

Posted: Mon Sep 02, 2019 9:01 am

by Atlantic 3279

I still have to pinch myself now and then to be sure that I'm not dreaming and that this incredibly neat construction really is taking place in 2mm scale....

Re: Copenhagen Fields & TFW’s workshop

Posted: Mon Sep 02, 2019 11:00 am

by manna

G'day Gents

Lovely build, I've just kicked myself, for 'Not' thinking to build the cab inside splashers 'Outside' the cab rather than fiddling about with them inside the cab.

manna

Re: Copenhagen Fields & TFW’s workshop

Posted: Mon Sep 02, 2019 12:38 pm

by john coffin

This should convince those who think soldering is hard, in 4mm, that actually it is easier than

the nay sayers keep moaning about.

Tim's finishing is so good, his fingers being so over-scale, actually make it look more untidy than it does in real life.

Perhaps we should ask Tim to do a beginners guide to soldering!!!!!!!

Paul

Re: Copenhagen Fields & TFW’s workshop

Posted: Mon Sep 02, 2019 3:07 pm

by Tim Watson

Thanks for the kind comments. In my soldering I use a lot of heat, generally phosphoric acid flux and 144 solder. I also spend a good deal of time cleaning up. Always remember that solder moves to where the heat is.

I have since realised that the cab splashers are incorrect and will be replaced.

Tim

Re: Copenhagen Fields & TFW’s workshop

Posted: Fri Sep 13, 2019 11:29 am

by Tim Watson

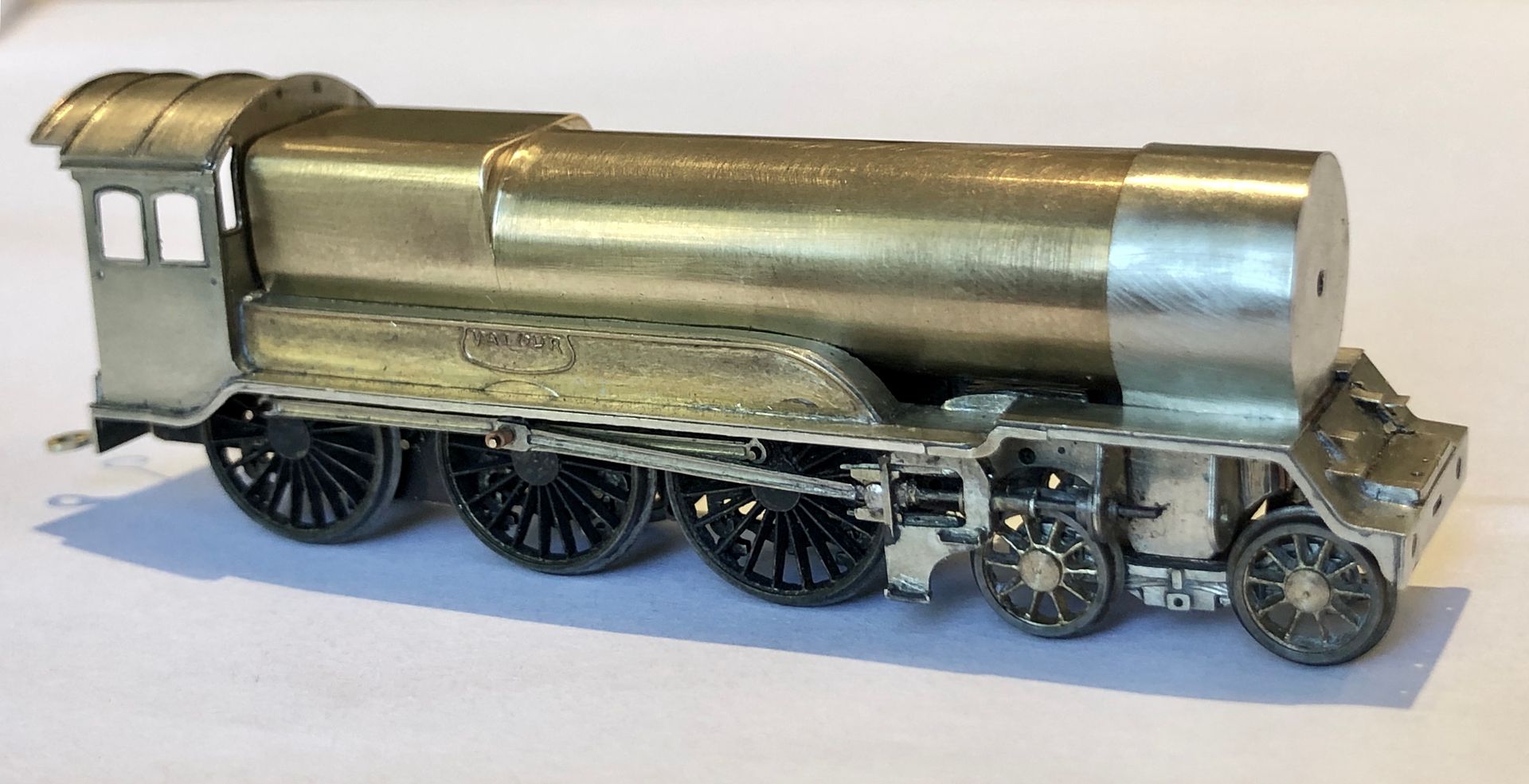

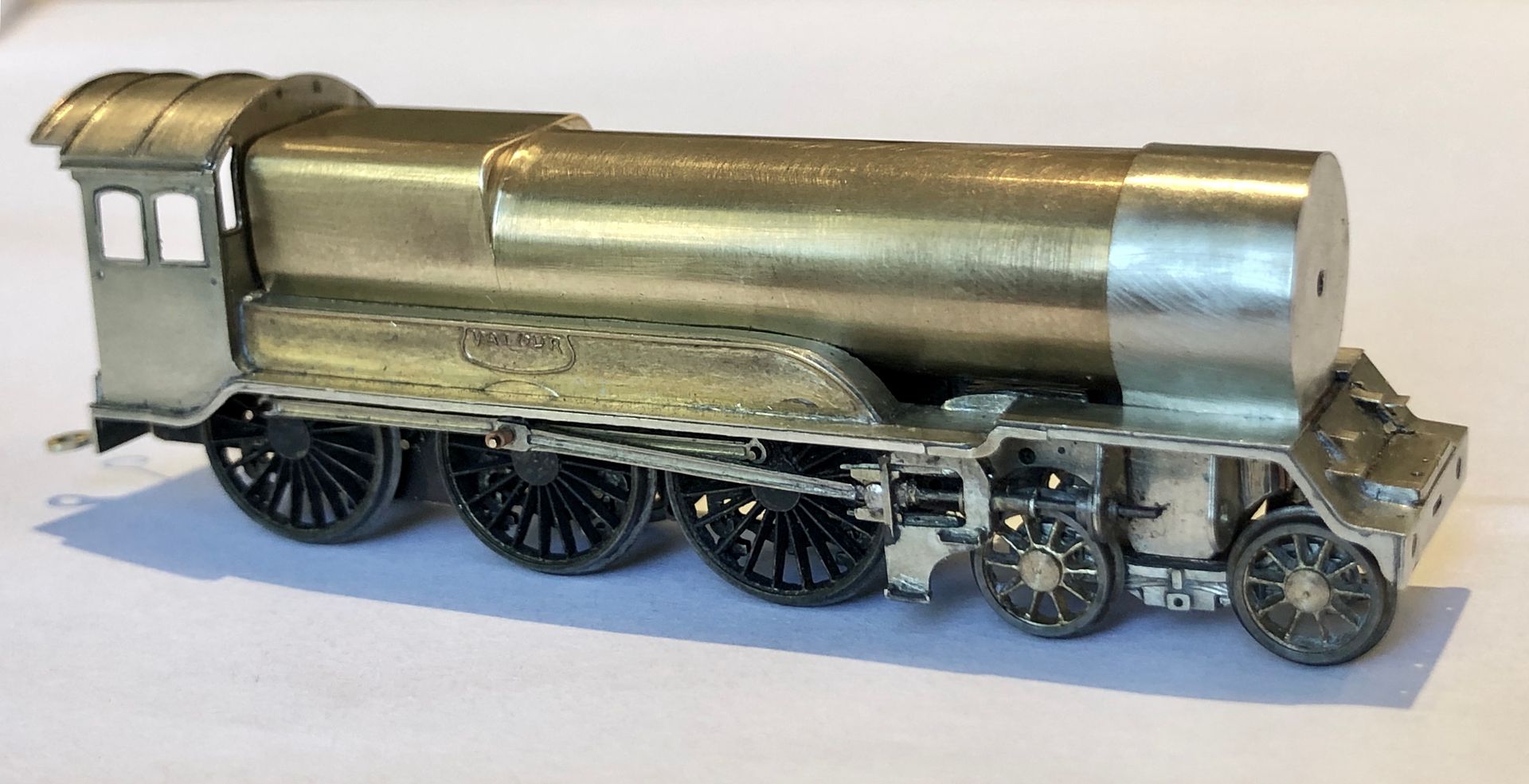

Valour now has a boiler and weighs in at 75g!

Tim

Re: Copenhagen Fields & TFW’s workshop

Posted: Fri Sep 13, 2019 12:45 pm

by Phil Brighton

I can't understand how you do this so neatly!

Loads of other pictures of this miniature work of art have stopped displaying, only the most recent remain.

Re: Copenhagen Fields & TFW’s workshop

Posted: Fri Sep 13, 2019 2:09 pm

by Tim Watson

Unfortunately, Tinypic has stopped working, so they would need to be replaced by my new server. Very tedious.

Tim

Re: Copenhagen Fields & TFW’s workshop

Posted: Fri Sep 13, 2019 4:48 pm

by john coffin

Very Nice Tim

thought it was only me who had lost the pics, but thankfully not.

Is it the photo, or is there a gap behind the firebox at the front of the cab, or are you as usual going to

blow us all away, by putting the firebox retaining straps there?

The belpaire looks really good, how did you make the front curve please?

Paul

Re: Copenhagen Fields & TFW’s workshop

Posted: Fri Sep 13, 2019 5:08 pm

by Tim Watson

The gap between the firebox and cab will have the relevant beading Paul - well spotted! The whole of the boiler and firebox was machined and filed from a lump of brass.

In this image the second cut is being made on the milling machine for the firebox from the oversized round end of the boiler.

Tim

Re: Copenhagen Fields & TFW’s workshop

Posted: Fri Sep 13, 2019 7:39 pm

by Atso

Just stunning Tim, amazing work.