Rob's bits and pieces which might be of interest, workbench

Posted: Sat May 28, 2022 12:27 pm

I am currently building a David Andrews Princess Royal kit which of course isn't remotely LNER so I haven't posted anything of the build but certain things to do with the build are universal so worth sharing.

Over on the Guild forum there was some discussion about lubricators, centred primarily on the potential difficulties of drilling out brass castings. This prompted me to look in the box and see what the lubricator castings were like as supplied.

They are nicely detailed castings, albeit missing the front and rear fittings. But, most importantly for this build, there are only two of them in the kit and we need three.

In a bit of a dilemma but not needing them right now, I sent an email off to the gent that I am building it for with a few options on how we might

proceed.

While awaiting a reply/phone call, I rose to the challenge and had a look through my material stock to see if I had any bar of a suitable size for making some myself.

I had a length of brass that was suitable, so I cut three lengths and machines them to the basic shape and size before drilling out the various holes.

Next, I turned the circular front piece that the pivot mechanism attaches to. Which gave me a chance to try out the grooving tool that I ground. I am pleased to say that by taking very light cuts, I was able to turn down a part with a 1mm spigot then a 3mm centre and a further 1mm spigot beyond the 3mm section without having to reverse the workpiece in the collet to turn the second spigot without snapping it off.

I then filed up and cut off around 50 small brass unions (I needed 42 but there were the inevitable pings off into space). It was only when I started to fit the blanking plugs on the front of two of the lubricators that I thought to take any photos.

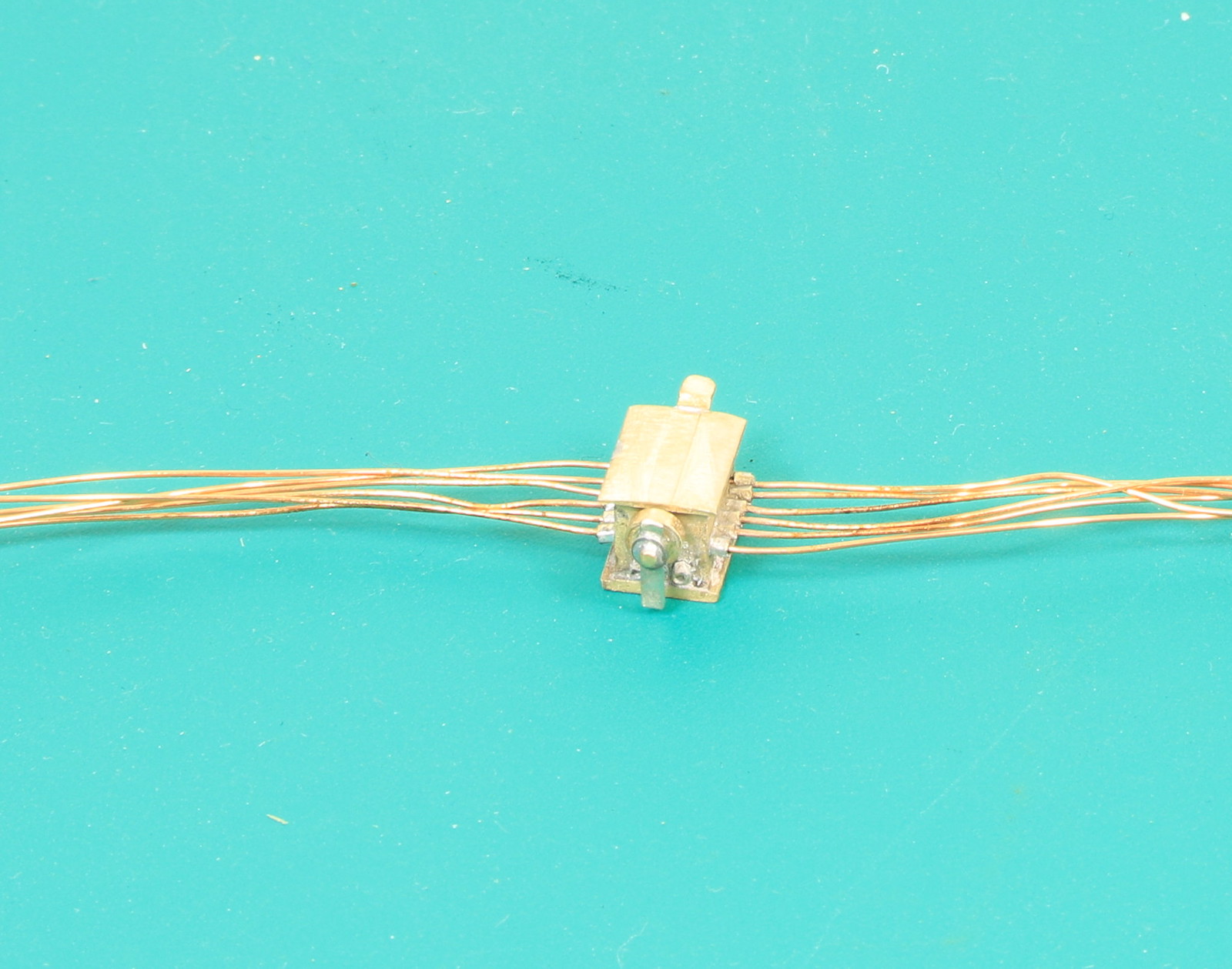

As you can see not all of the holes were dead in line due to the small drill wandering a little because I drill right through rather than from each side. But I had a cunning plan to get around that.

The holes through the bodies were 0.5mm but the copper wire that I am using for the pipes is only 0.3mm. The smallest microbore tube that I had for making the unions has a 0.5mm id so I had quite a bit of wiggle room to line them up as I fitted them.

The rocking [ shaped pieces on the rear, were made from some slices cut from a length rectangular brass tube that I have had in my stock box for 10 years or more. I don’t seem to use it often and then only in small slices but it’s handy to have and more rigid that if I had bent up some strip.

Over on the Guild forum there was some discussion about lubricators, centred primarily on the potential difficulties of drilling out brass castings. This prompted me to look in the box and see what the lubricator castings were like as supplied.

They are nicely detailed castings, albeit missing the front and rear fittings. But, most importantly for this build, there are only two of them in the kit and we need three.

In a bit of a dilemma but not needing them right now, I sent an email off to the gent that I am building it for with a few options on how we might

proceed.

While awaiting a reply/phone call, I rose to the challenge and had a look through my material stock to see if I had any bar of a suitable size for making some myself.

I had a length of brass that was suitable, so I cut three lengths and machines them to the basic shape and size before drilling out the various holes.

Next, I turned the circular front piece that the pivot mechanism attaches to. Which gave me a chance to try out the grooving tool that I ground. I am pleased to say that by taking very light cuts, I was able to turn down a part with a 1mm spigot then a 3mm centre and a further 1mm spigot beyond the 3mm section without having to reverse the workpiece in the collet to turn the second spigot without snapping it off.

I then filed up and cut off around 50 small brass unions (I needed 42 but there were the inevitable pings off into space). It was only when I started to fit the blanking plugs on the front of two of the lubricators that I thought to take any photos.

As you can see not all of the holes were dead in line due to the small drill wandering a little because I drill right through rather than from each side. But I had a cunning plan to get around that.

The holes through the bodies were 0.5mm but the copper wire that I am using for the pipes is only 0.3mm. The smallest microbore tube that I had for making the unions has a 0.5mm id so I had quite a bit of wiggle room to line them up as I fitted them.

The rocking [ shaped pieces on the rear, were made from some slices cut from a length rectangular brass tube that I have had in my stock box for 10 years or more. I don’t seem to use it often and then only in small slices but it’s handy to have and more rigid that if I had bent up some strip.