By extreme good fortune this year I have taken photos of both. I had forgotten the other until today though.

The first one is located at Shildon, attached to the C1 large-boilered Atlantic and, as proposed in a recent post, I asked one of the museum assistants if I could be accompanied aboard to take photos of the tender top on Saturday and he obliged.

The other is attached by coincidence to the small-boilered Atlantic Henry Oakley whom I encountered at York earlier in the year. Although not great and I didn't get aboard, I did get enough details from my photos to work out which version I need for the J6 and more importantly that the coal space on the kit isn't quite like the two preserved examples each of which are similar but different.

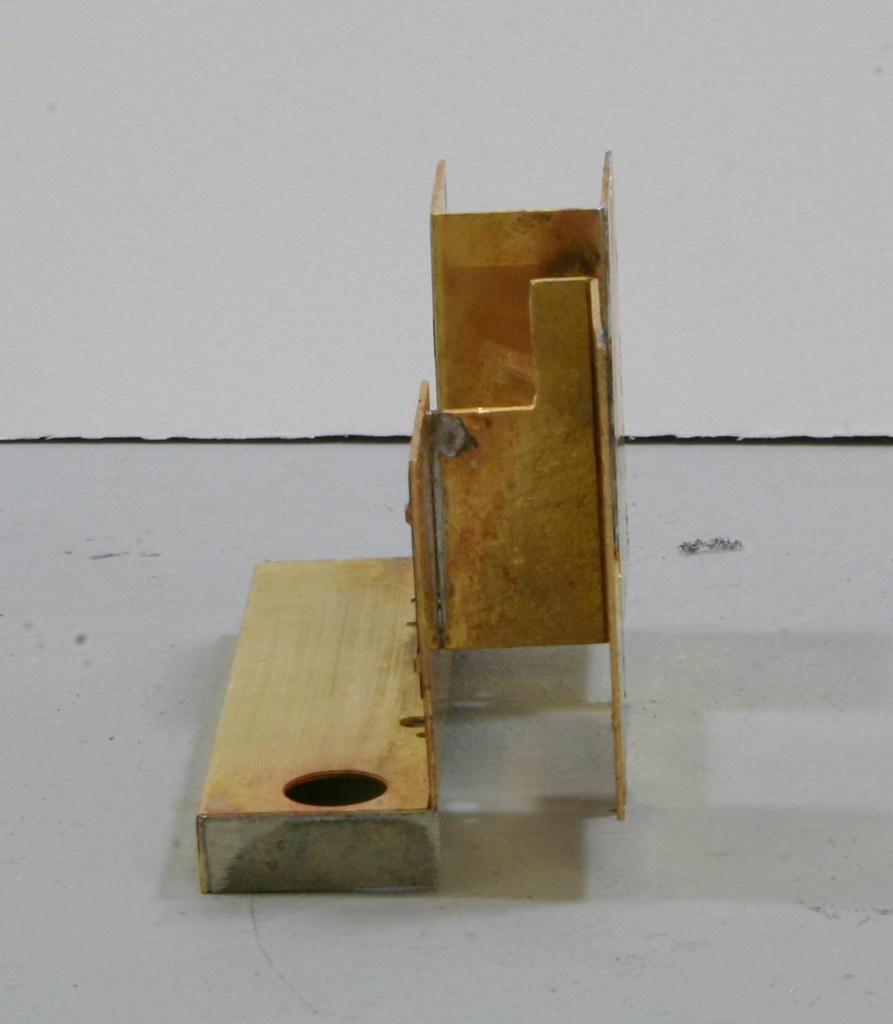

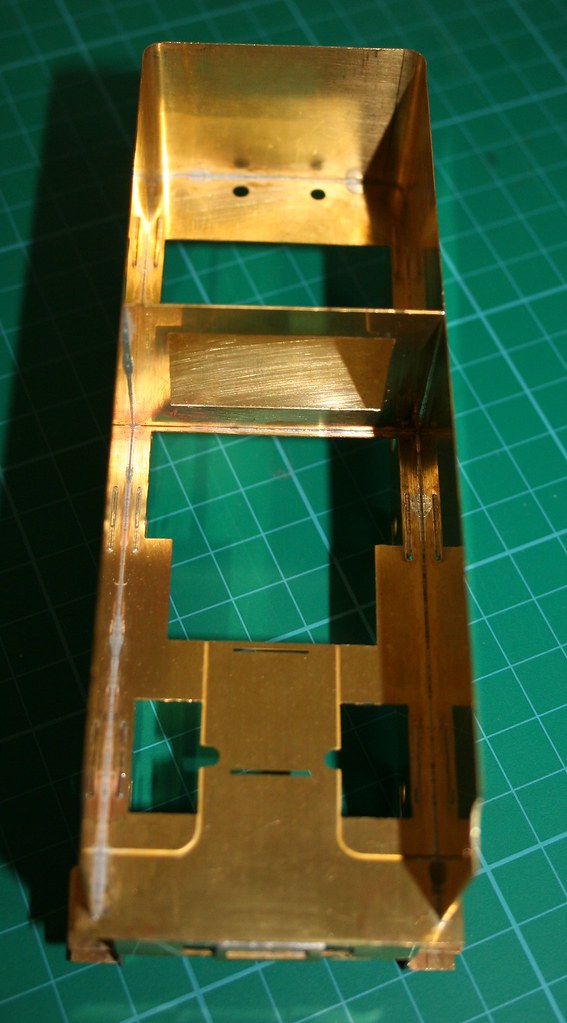

Firstly what the kit looks like:

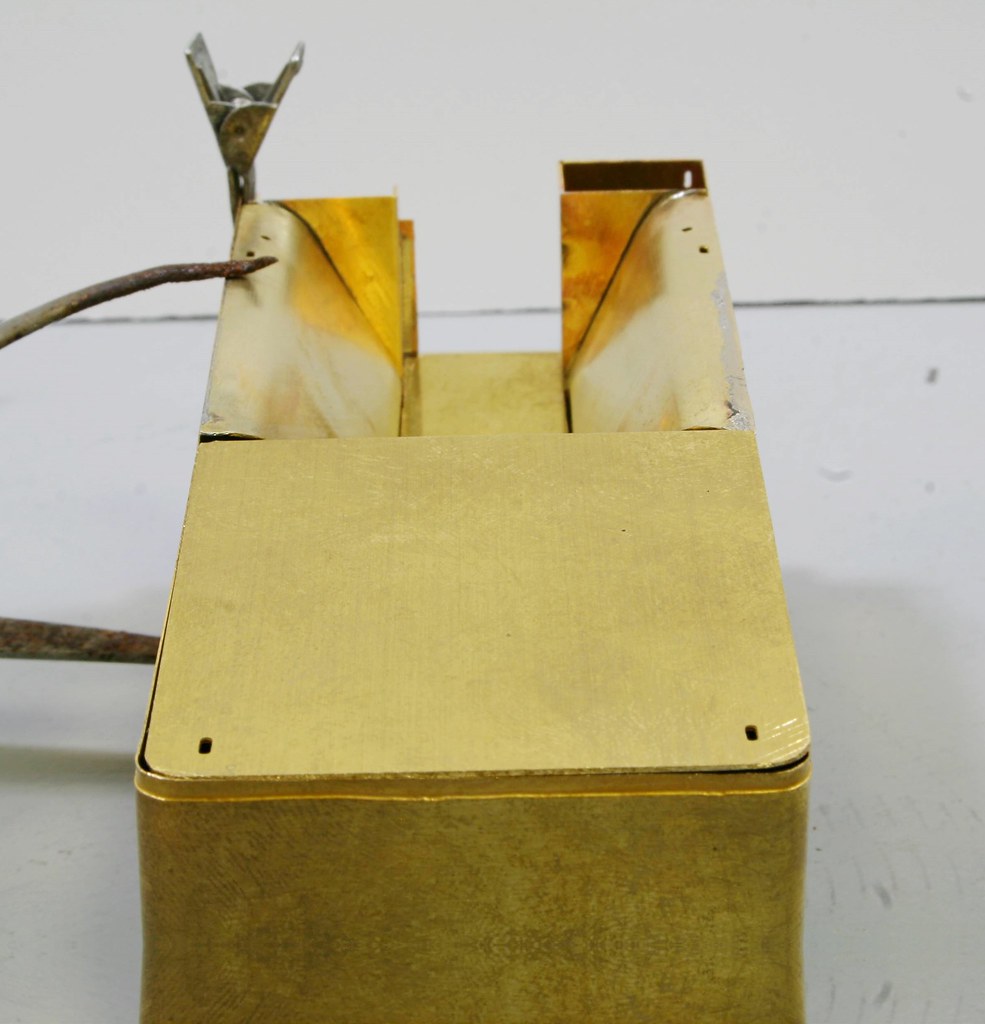

Next the tender attached to the Large Atlantic

I have more detailed photos of the tender top on my Flickr site but these will suffice to tell the story to date.

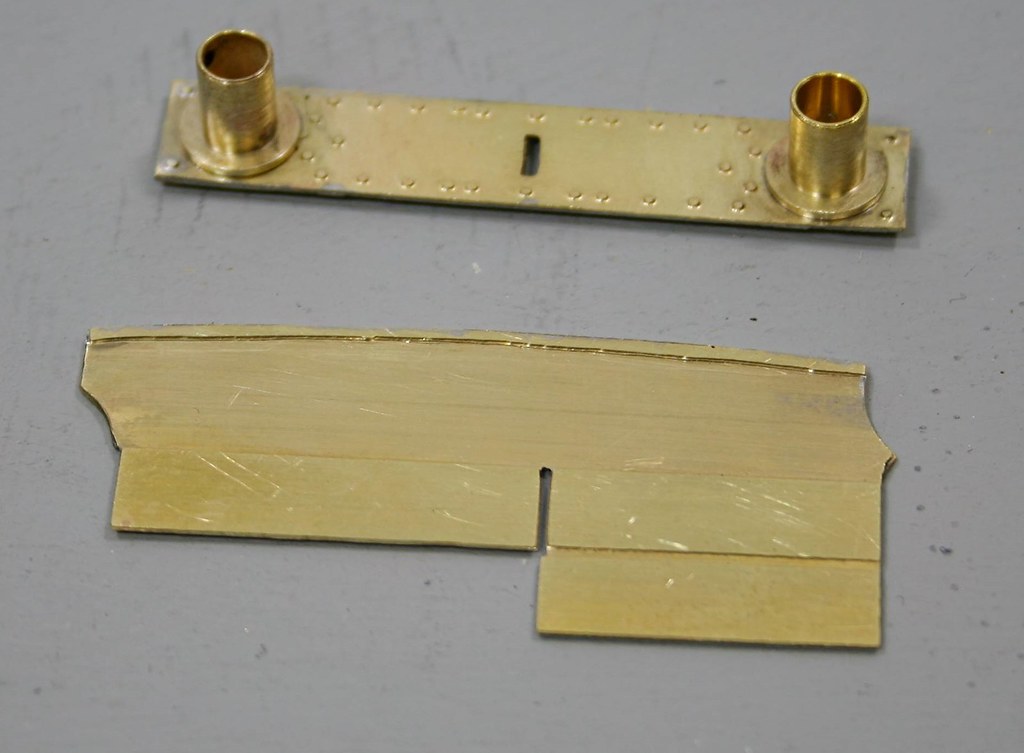

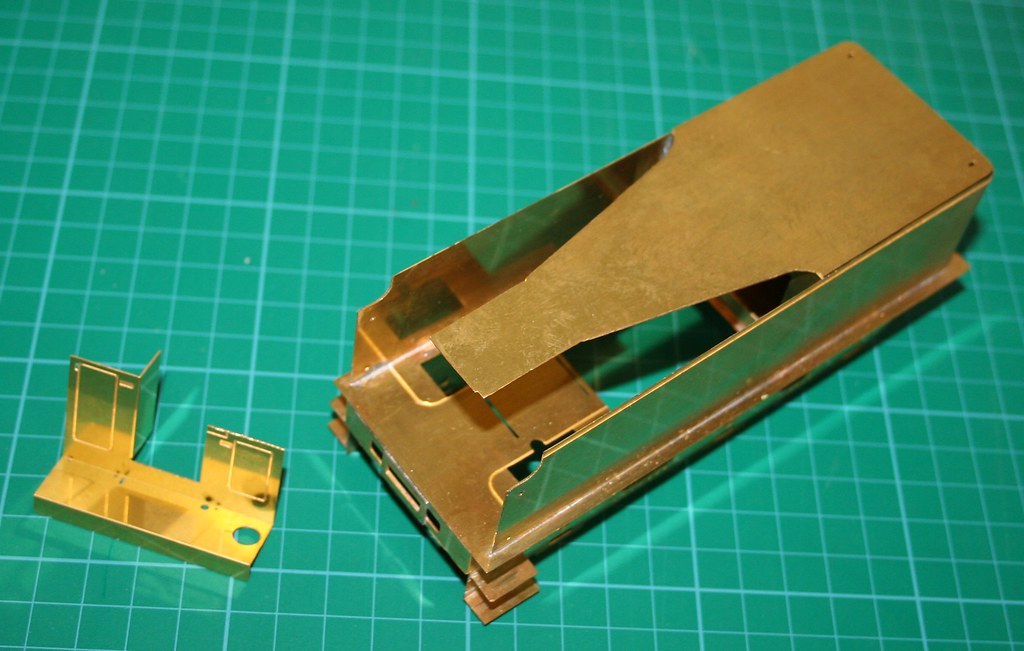

Lastly the tender attached to Henry Oakley and the one which I believe that I need for the J6 when compared to the couple of photos I have of the prototype – no 64206 and more importantly the type that I believe the kit is meant to represent (unless there was a third type which looked externally the same.

As I said, not the best photos but they do show that one side is higher than the other and there is a representation of lockers albeit the prototype show a small door on the higher side whereas the etch has a full height door. The key difference though is in the coal space. Both types of tender have a parallel rather plain functional coal space and I would be surprised if there was a third type that had one with the sloping sides that are inferred by the etches. I think that Malcolm Crawley got it wrong when he designed the tender kit but I would be happy to be corrected in that assumption.

Unless some evidence comes to the fore fairly soon to tell me that I am wrong I intend to modify the coal space to be more like that of the tender attached to Henry Oakely.